The 7-Second Trick For Dust Extractor Vs Shop Vac

Table of ContentsDust Extractor Vs Shop Vac Things To Know Before You BuyAn Unbiased View of Dust Extractor Vs Shop VacAbout Dust Extractor Vs Shop VacThe Ultimate Guide To Dust Extractor Vs Shop VacThe Greatest Guide To Dust Extractor Vs Shop VacThe Basic Principles Of Dust Extractor Vs Shop Vac

The challenges for factory dust collection systems focus on crystalline silica dirt, carbon monoxide, as well as warm, which are poisonous combinations. These aspects make conference air top quality requirements challenging and also requiring. When choosing a dust control system for a foundry, the initial factor to consider is the ability of the unit to hold up against rough and also harmful work environment problems.Apart from the evident conditions, the picked equipment has to meet the regulations of OSHA, the EPA, and also the NFPA. To satisfy those standards, dust collection systems employ shakeout units, collection hoods, melt, mold and mildew pouring, cooling hoods, and also exhaust heaps. Pleated bag and cartridge-style collectors have a very effective filtration system along with a small dimension and also reduced pressure decline.

Dirt collection systems for this type of procedure must be especially developed to fit the type of layer being applied. The purpose of the system is to regulate and lessen overspray as well as dirt.

Dust Extractor Vs Shop Vac - The Facts

It would seem most likely to raise air movement and also activity, this type of remedy might be inefficient and also waste energy. The layout of the booth relies on the pressure of the air entering the cell or cubicle. For most systems, it is very important to have a slight vacuum in the booth to stay clear of possible favorable stress.

Another approach is just positioning the makeup air link on the top of the booth. Despite the layout, it is essential for the cleansing of the air to have cross ventilation. Similar to a cleanroom, airflow in a thermal spray booth can be either horizontal or downward, though the downward design is best for dirt collection systems. dust extractor vs shop vac.

The pharmaceutical market is a very regulated market with considerable and precise guidelines. Dirt from pharmaceuticals is created primarily during the production and packaging of items - dust extractor vs shop vac. Each step of creating a medicine, which consists of granulating, drying, blending, pressing, layer, and grinding, produces huge quantities of dust that need to be gotten rid of.

9 Easy Facts About Dust Extractor Vs Shop Vac Explained

HEPA filters are typically located in pharmaceutical dust control systems given that they are one of the most effective as well as trustworthy. As with a factory system, they are set up as a second security to accomplish zero emissions. Recycling generates a great deal of dust as an all-natural outcome of reducing things to their basic materials.

Dirt comes from after products are shredded, crushed, or have paint or lacquer got rid of. All recycling facilities are called for to stick to air top quality requirements. As they function to meet high quality standards and also control toxins, they have actually acknowledged that dirt control is a significant issue, bring about the vast use dust collection systems to minimize and also consist of the problem.

7 Simple Techniques For Dust Extractor Vs Shop Vac

When manufacturers select a dirt control system, they are advised by manufacturers concerning the type of system that would certainly best fit their requirements considering that buying as well as setting up a dirt control system is a major financial investment. Particulate issue can be found in a variety of forms, from silicon dirt to timber chips and sawdust.

Below is a list of the sorts of particles that dust collection systems can remove. Plaster Plaster needs a high-efficiency baghouse system efficient in running at temperatures near 428 F (220 C). Felt Felt is utilized in apparel production and also calls for dirt collection systems at 3 stages of the process.

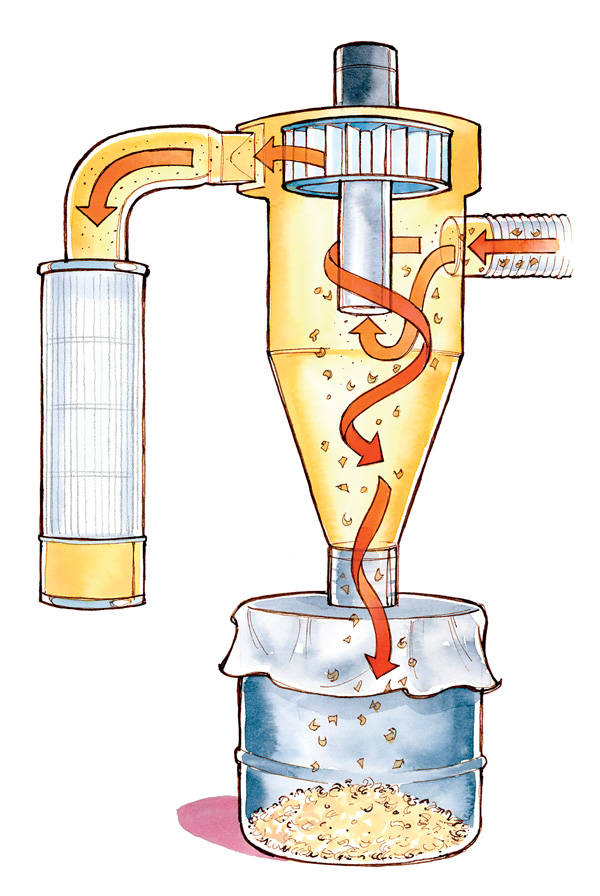

Sawdust This is the most typical material gotten rid of by dirt collection systems. Cartridge or baghouse methods can be utilized, with baghouse try this website being the most efficient.

Rumored Buzz on Dust Extractor Vs Shop Vac

Textile filter bags in a cartridge system are the most efficient approach for accumulating dirt. Concrete Concrete dirt is developed throughout the activity and transportation of the product. Dirt collection systems are covered to have the check that dust and clean the air. Clay Clay dust is generated in the manufacturing of bricks.

With the introduction of dirt collection systems, workers are much safer as well as more protected. Sugar Sugar dust is the spin-off of the production of sweet. Pulse jet systems are made use of to maintain the filters of the dirt collection system particulate-free. The gathered material is eliminated as well as collected in drums. Zinc Zinc dust is produced in the galvanizing procedure.

Fascination About Dust Extractor Vs Shop Vac

A baghouse system is the preferred system. Rice Dirt Rice dust has extremely fine and also minute fragments that accumulate throughout the production of rice-based products. A dirt collection system is needed for the security as well as safety of workers. Silica Silica is just one of the most typical substances on earth. It is a main component of a number of manufacturing operations, such as the manufacturing of glass, ceramic floor tile, concrete, and asphalt.